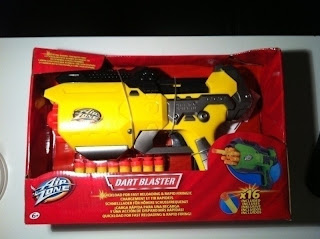

This is the octo-shot!

(which is a modded triple shot)

With the right spring and proper modding it can get ranges of 140ft

Here is the vid to prove it

Full write up after the jump!

After I first built it and fired several shots, I opened it back up to find MANY stress points. As you know, the plastic used in this gun is very cheap!

As you can see, I've epoxy puttied the plunger tube support and the rotation sled support towards the front of the gun (on both halves).

Here you can see how I've puttied around the catch support and the rear plunger tube support.

...the other half

I've since added putty here, around the trigger and added an extra spring. The plastic for the trigger guide is particularly flimsy.

Here's the priming handle with foam and hot glue. The foam and hot glue used throughout the blaster is for sound muffling and an attempt to minimize the cheap plastic sound that it makes when handling it.

I also added epoxy putty to the front of the shell around the area that supports the turret towards to top part of the shell. for some reason this area (stock) is very flimsy as well. I suggest doing this, even for your Quadshots.

Once the blaster is put back together, I added an extra spring here for the catch...

...because of the main spring I chose.

This is how I handled my turret to plunger seal.

This is how I handled my turret to plunger seal.

I cut a 1/2 inch of 3/4 inch CPVC and beveled the inside (both ends) with a Dremel like so:

The suction cup has a little nub thing on the back that you have to cut off.

I superglued the suction cup into the CPVC.

Once I did that, I Dremeled out the center, e-taped, gooped and nested the stock white thing inside. This creates a wider surface area covering more of the rear loading holes in the new turret.

To quote ForsakenAngel24, "SACRFICE!!!!"

After I brought this up to the alter, held up my mighty screw driver and cut out it's still beating heart, I placed it in boiling water to loosen the glue towards the front of the turret. The part that looks kind of like a star. Poor thing never got to blow it's load... not even once.

sorry no pics of the procedure.... yet

Here you can get an idea of what I had to do. I cut around the barrels leaving 1/2 an inch for my new barrels to be nested in, being very careful not to cut or damage the center post.

For the new barrels to nest in snugly, I also had to Dremel out the remaining barrels. It took me quite a while to achieve this, I didn't want to ruin it now.

I had to cut off a little bit of the back of the turret-mech to make it fit in the LSG. Don't cut it too short. Make it fit EXACTLY.

The back of the turret has a lot of holes/spaces. I thought about hot gluing or epoxy puttying them but I knew I could never get a smooth surface. My solution was this:

...a duo-tang folder. I sized and cut out a circle to fit. Super glued it careful to make sure that it completely covered the soon-to-be rear loading holes. The translucent plastic helped with being able see the rear loading holes to Dremel out.

The turret fits in perfectly with the shell. With the new plunger seal, it pushes quite heavily against the turret, but with the added support to the front shell (shown earlier) it shouldn't be a problem.

THERE YOUZ ALL GO!!!

Put it all back together and you have an Octo-shot!

Watch out. This post may cause premature orgasms.

ReplyDeleteDoesn't MIG have a freak of nature octoshot that shoots 200'?

ReplyDelete